![]() Bulletin E-90-BPC

Bulletin E-90-BPC

Series 4B, 8B, 16B kunye 32B Microprocessor

Ulawulo Lwenkqubo Yobushushu obusekwe

Iinkcukacha-Imiyalelo yokuFakela kunye nokuSebenza

Incwadi Yemiyalelo

UQONGA LWENOMBOLO YOMfanekiso

NDIYAQALISA

- Faka ulawulo njengoko kuchaziwe kwiphepha lesi-4.

- Faka ulawulo lwakho ngokulandela imiyalelo ekwiphepha 6-7. Nceda ufunde icandelo lokuQaphela elibekwe ekupheleni kwale ncwadana phambi kokuba ufake iintambo zolawulo.

- Ukufumana iziphumo ezilungileyo xa utshintsho lweprogram luyimfuneko, yenza zonke iinguqu kwimodi yokuSeta yokuQala (Amaphepha 20-22) ngaphambi kokuba wenze utshintsho kwiNdlela yoLawulo (Amaphepha 17-19) okanye i-Operation Mode (Amaphepha 15-16). Ukuba kukho nayiphi na imiyalezo yemposiso eyenzekayo, jonga iCandelo loMyalezo wemposiso yoDiagnostic (Iphepha 26) ngoncedo.

UKUFAKWA

Faka isixhobo kwindawo engayi kuba phantsi kobushushu obugqithisileyo, ukothuka, okanye ukungcangcazela. Zonke iimodeli zenzelwe ukunyuswa kwiphaneli evalelweyo.

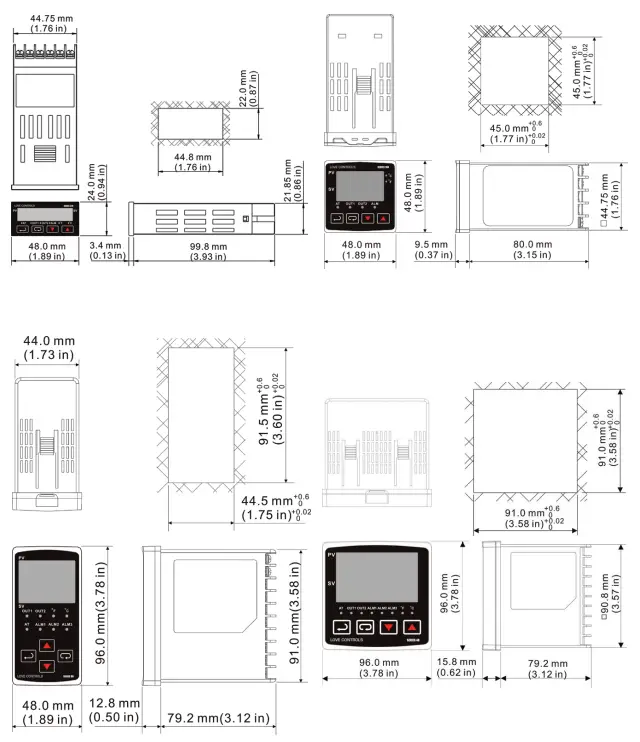

Khetha indawo efunwayo kwisixhobo kwindawo yolawulo. Lungiselela indawo yolawulo ngokusika kunye nokucima ukuvuleka okufunekayo ngokwephaneli yokusika imilinganiselo edweliswe ngezantsi. Landela imiyalelo yokunyuswa edweliswe kwiphepha lesi-5. Okokugqibela, faka ucingo kwisilawuli ngokwedayagram efanelekileyo yocingo edweliswe kwiphepha lesi-6.

PANEL CUTOUT DIMENSIONS

INDLELA YOKUFAKA

Inyathelo 1: Ukusuka ngaphambili kwephaneli, tyibilikisa isilawuli sendlu ngokusikwa. I-gasket yendlu kufuneka ichasene neflange yendlu ngaphambi kokufaka.

Inyathelo lesi-2: Faka izibiyeli zokuxhoma kwiigrooves ezinyukayo phezulu naphantsi kwesilawuli (16B, 8B, kunye ne-4B). Kwi-32B, tyibilikisa ikhola yokukhwela phezu kwendlu ukusuka ngasemva kwendawo yolawulo.

Inyathelo lesi-3: Tyhiliza izibiyeli zokuxhoma phambili de isibiyeli siyema kudonga lwephaneli.

Inyathelo lesi-4: Faka kwaye uqinise izikrufu kwisibiyeli ukuze ukhusele isilawuli endaweni. (I-torque ye-screw kufuneka ibe yi-0.8 kgf-cm).

Ukunyuswa koFakelo lweBracket

16B/4B/8B Indlela yokuNqamisa

32 Indlela yokuNqamisa

I-WIRING

Musa ukuqhuba i-thermocouple okanye enye i-wiring yeklasi kwi-conduit efanayo njengoko ukhokela amandla. Sebenzisa kuphela uhlobo lwe-thermocouple okanye i-RTD probe apho ulawulo lucwangciswe khona.

Gcina ukwahlukana phakathi kwe-wiring ye-sensor, i-axiliary in or out, kunye nezinye ii-wiring. Jonga i-Initial Setting Menu ukuze ukhethe igalelo.

Ngegalelo le-thermocouple soloko usebenzisa izikhokelo zolwandiso lohlobo olufanayo olulungiselelwe i-thermocouple yakho.

Xa unxibelelanisa unikezelo sebenzisa iNombolo ye-16 AWG okanye iingcingo ezinkulu ezireyithwe ubuncinci 75˚ C. Sebenzisa izikhondatha kuphela. Wonke umgca voltagIisekethe ze-e output kufuneka zibe nokuqhawula okuqhelekileyo kwaye zidibaniswe kwipali efanayo yokuqhawula.

i-input wiring kwi-thermocouple, yangoku, kunye ne-RTD; kunye neentambo eziphumayo ze-14 VDC zangoku zithelekelelwa IKLASI 2.

Lawula iingcingo njengomboniso ongezantsi:

Ukuchongwa kwetheminali

Ukuchongwa kwetheminali (Kuyaqhutywa)

Iingcingo ze-4 ukuya kwi-20 mA iiNgeniso zokuThumela

Phawula: I-16B yoyilo lwetheminali esetyenziswe ngasentla example. Sebenzisa uyilo olufanelekileyo lwetheminali kumlawuli okhethiweyo.

IMISEBENZI ENGUNDOQO PHAMBILI

Imisebenzi ephambili yile ilandelayo:

| ISALATHISO: Ukucofa iqhosha le-INDEX kuqhubela phambili isiboniso kwinto elandelayo yemenyu. | |

| I-ARROW EKUPHEZULU: Yongeza ixabiso okanye utshintshe into yemenyu. Ukuba icinezelwe ngexesha leNdlela yokuSebenza, ixabiso lendawo yokumisela liya kwandiswa. | |

| I-ARROW PHANTSI: Yehlisa ixabiso okanye utshintshe into yemenyu. Ukuba icinezelwe ngexesha leNdlela yokuSebenza, ixabiso lendawo yokumisela liya kuncitshiswa. | |

| NGENA: Igcina ixabiso okanye utshintsho lwento. Ukuba ayicinezelwa, ixabiso eligcinwe ngaphambili okanye into iya kugcinwa. Xa ucinezelekile ngexesha leNdlela yokuSebenza, umlawuli utshintshela kwiNdlela yoLawulo. Ukuba ibanjelwe ngaphezu kwemizuzwana emi-3 ngexesha leNdlela yokuSebenza, umlawuli utshintshela kwiNdlela yokuSeta yokuQala. Ukuba icinezelwe ngexesha leNdlela yoLawulo okanye iModi yokuSeta yokuQala, umlawuli uya kubuyela kwiNdlela yokuSebenza. |

IIMPAWU ZOKHUSELEKO

Umlawuli wechungechunge lwe-B uneendlela ezimbini ezakhelwe kwiisetingi zokutshixa ukukhusela abasebenzi abangagunyaziswanga ekutshintsheni izicwangciso zeparameter. Ezi parameters zisetwe kwi-Operation Mode.

Isicwangciso se-LoC1 sichaphazela zonke iiparameters kumlawuli. Ukuba isicwangciso se-LoC1 senziwa, umsebenzisi kuya kufuneka avule isilawuli ukwenza naluphi na utshintsho kwiiparamitha zomlawuli.

Isicwangciso se-LoC2 sichaphazela zonke iiparamitha ngaphandle kwendawo emiselweyo. Ukuba isicwangciso se-LoC2 senziwa, ekuphela kwepharamitha aya kukwazi ukuyitshintsha umqhubi yindawo yokumisela. Ukuze utshintshe nayiphi na enye iparameters, umqhubi uya kufuneka avule ulawulo ngaphambi kokuba enze utshintsho.

Ukuze uvule ulawulo, umsebenzisi kufuneka acinezele iqhosha le-ENTER kunye ne-INDEX ngaxeshanye.

ULAWULO INGCACISO YOMSEBENZI

I-HOME ibonisa isiqhelo ngelixa ulawulo lusebenza. Ukuba akukho ziphoso okanye imisebenzi esebenzayo, isiboniso EKHAYA siya kubonisa Uguquguquko Lwenkqubo (ubushushu, uxinzelelo, ukuqukuqela, %RH, njl.njl.) elinganiswa kumboniso ophezulu kunye neSeti eguquguqukayo kumboniso ongezantsi.

Izinto ezinokutshintsha i-HOME display yi-Ramp kwaye Soak umsebenzi kunye nayiphi na imiyalezo yemposiso. Iinkcazo zale miboniso ikhethekileyo ziyalandela.

Ukuba iRamp kunye nenqaku leSoak liyasebenza, emva koko umboniso osezantsi uza kubonisa ipateni yophumezo yangoku kunye nenyathelo lophumezo lwangoku. I-UP kunye ne-PHANSI iintolo zinokucinezelwa ukutshintsha umboniso osezantsi ukubonisa iNdawo yokuSeta (SP) yenyathelo langoku lophumezo okanye iXesha Eliseleyo (r-ti) yenyathelo langoku lophumezo. Emva kokutshintsha isiboniso esisezantsi nokuba yiXesha Eliseleyo okanye iNdawo yokuSeta, iqhosha le-ENTER kufuneka licinezelwe ukubonisa amaxabiso.

Imiyalezo yemposiso ibonisiwe kwiphepha lama-26.

UKHETHO

Igalelo loMnyhadala

Xa umlawuli eyalwe ngoKhetho loNgeniso lweSigigaba (Jonga iphepha lesi-3 ngolwazi lokuodola), iingeniso ezimbini zesiganeko ziyafumaneka. Igalelo lesiganeko libangelwa kukuvalwa koqhagamshelwano phakathi kwesiganeko 1 (EV1) okanye isiganeko (EV2) i-terminal yoqhagamshelwano kunye nomhlaba wesignali (SG) i-terminal yoqhagamshelwano.

Isiganeko 1 silawula ukusebenza kwemveliso yolawulo. Xa isiganeko 1 iiterminal zoqhagamshelwano zivuliwe, imveliso iyasebenza. Xa isiganeko se-1 i-terminals yoqhagamshelwano ivaliwe, imveliso ivaliwe.

Iziphumo nazo zinokulawulwa nge-Run/Stop parameter usebenzisa ikhiphedi yangaphambili okanye ngokusebenzisa i-RS-485 yonxibelelwano.

Isiganeko se-2 sivumela umsebenzisi ukuba atshintshe phakathi kwamanqaku amabini okushisa. Indawo nganye yokubeka iqondo lokushisa ineeparamitha zokulawula ezizimeleyo.

Umsebenzi weAlam yeTransformer yangoku

Inketho ye-transformer yangoku ivumela umsebenzisi ukuba abe ne-alarm contact trigger ngenxa yokulahlekelwa kwangoku okanye ukunyuka kwangoku kwisiphumo solawulo. Xa usebenzisa igalelo le-transformer yangoku, umfowunelwa we-alam ofunekayo kufuneka usetelwe kuhlobo lwe-alam 13 kwi-Initial Setting Menu (Iphepha 21). I-transformer yangoku kufuneka ifakwe intambo ngokuhambelana nomzobo wocingo olufanelekileyo kwiphepha lesi-6 kunye nephepha 7. Amanqaku aphezulu kunye ne-alarm asezantsi anokusetwa ukusuka kwi-0.5 ukuya kwi-30 Amps. Isisombululo somboniso ngu-0.1 Amps kunye nokuchaneka ±0.5 Amps kunye ne-transformer yangoku efakiweyo.

Ukufudumeza, ukuPholisa okanye uLawulo lwe-Loop kabini

Ulawulo lobushushu lunokufumaneka ngokufudumeza okanye ukupholisa. Kubalawuli bechungechunge lwe-B, ukufudumeza kunye nokupholisa kungaqhutywa ngaxeshanye usebenzisa i-Dual Loop Output Control ukugcina indawo yokumisela iqondo lokushisa. Xa kusetyenziswa uLawulo lokuPhuma kweLuhlu oluBini lweLuphu lusetyenziswa, iziphumo zolawulo kufuneka ziqhagamshelane nezixhobo zokufudumeza kunye nokupholisa. Nceda ubhekisele koku kulandelayo ekusebenzeni kwesetingi nganye.

Iindlela zoLawulo zikhethwa ngokutshintsha iparamitha ye-S-HC kwiNdlela yokuSeta yokuQala.

Khetha UKUSHISA, ukufudumeza okanye ukubuyisela umva ulawulo olubambeleyo kwimveliso 1. Ukuba ikhethiwe, imveliso yesi-2 iya kuba yi-alam 3.

Khetha i-CoolL, yokupholisa okanye ukulawula ngokuthe ngqo kwimveliso 1. Ukuba ikhethiwe, imveliso yesi-2 iya kuba yi-alam 3.

Khetha i-H1C2 okanye i-C1H2 yoLawulo lweZiphumo eziNcinci ezimbini kwimveliso ye-1 kunye ne-2. Ukuba i-H1C2 ikhethiwe, imveliso yesi-1 iyakuba yeyokuqala kokufudumeza okanye ukubuyisela umva ulawulo olubambeleyo kunye nesiphumo sesi-2 siya kuba sesokupholisa okanye ukulawula ngokuthe ngqo. Ukuba i-C1H2 ikhethiwe, imveliso ye-1 iya kuba yeyokupholisa okanye ukulawula ngokuthe ngqo kunye nemveliso ye-2 iya kuba yeyokufudumala okanye ukubuyisela ukubuyisela ulawulo.

Ukucwangcisa imo yolawulo kwi-PID xa umlawuli emiselwe uLawulo lweZiphumo eziDityanisiweyo Lusebenzisa i-Parameter ye-Proportional Band Coefficient (CoEF) kunye ne-Dead Band (efile).

I-Proportional Band Coefficient (CoEF) imisela ixabiso lebhendi eLungeleyo kwiSiphumo sesi-2 ngokusekwe kwiNqanaba loMlinganiselo lemveliso 1. UmGangatho oLungeleyo weSiphumo 2 uya kulingana neBand yoMlinganiselo (Pn) yeSiphumo soku-1 esiphindaphindwe ngeBand yoMlinganiso yeBand (CoEF). Ixesha eliDityanisiweyo (ngaphakathi) kunye neXesha lokuPhuhliswa (dn) liya kufana kuzo zombini iziPhumo.

I-Dead Band (dEAd) ipharamitha ibeka indawo apho iziphumo zokufudumeza kunye nokupholisa zisebenza kwi-0% kwi. I-Dead Band igxile kwiNdawo yokuSeta kwimowudi yoLawulo lokuPhuma kweLuphu eDual. Nceda ujonge iBandi labafileyo eliboniswe kwiphepha 19.

RAMP/LONGA INKQUBO NOKUSEBENZA

I-ramp/ i-soak feature inika ukuguquguquka okukhulu ngokuvumela utshintsho kwindawo emiselweyo ukuba lwenziwe kwixesha elimiselweyo.

Ithiyori yokuSebenza

Ulawulo B series zinika indlela elula kakhulu inkqubo aramp umsebenzi. Kunokuba ifune umsebenzi wokubala ireyithi yokusondela (ngokuqhelekileyo kwiidigri ngemizuzu), uthotho lwe-B lubalela ngaphakathi. Ngaloo ndlela, umqhubi ufuna kuphela ukucwangcisa indawo ekujoliswe kuyo kunye nexesha elinqwenelekayo ukufikelela kuloo ndawo. Xa i-ramp icandelo lenziwa lulawulo, libala i ramp efunekayo ukususa inkqubo ukusuka kwixabiso lokuqala (i-PV yangoku) ukuya kwixabiso elifunekayo (i-SP ecwangcisiweyo) ngexesha elivunyelweyo.

Iisofu (okanye iindawo zokuhlala) zi-ramp amacandelo apho indawo ekujoliswe kuyo iyafana nexabiso lenkqubo yokuqala. Oku kuvumela ezininzitageramps ngaphandle kokumosha amanyathelo okuthambisa aphakathi.

Kufuneka kuthathelwe ingqalelo, nangona kunjalo, ukuba inkqubo ifikelele kwixabiso le-soak ngaphambi kokuba ixesha lokufunxa liqale. Ukuba akunjalo, icandelo elilandelayo liya kubala ithambeka ukusuka kwi-PV yokuqala ukuya kwi-SP ekujoliswe kuyo. Ngokuxhomekeke kwiimfuno zakho zenkqubo, lo mahluko unokubaluleka.

Qinisekisa ukuba uvavanya nayiphi na inkqubo ngeziphumo ezinqwenelekayo phambi kokuba usebenzise imathiriyeli yemveliso.

Musa ukusebenza auto-tuning ngelixa aramp umsebenzi uyasebenza. I-ramp umsebenzi uya kuthintela ukuzishuna ekusebenzeni kakuhle. Qinisekisa ukuba lonke ulungelelwaniso lusetiwe ngaphambili

ukusebenza ramp/sok.

Ukuseta inkqubo

Yonke inkqubo yeRamp/Soak umsebenzi wenziwa kwiNdlela yokuSeta yokuQala. Unganqwenela ukwenza inkqubo yakho ephepheni phambi kokungena kulandelelwano lwemenyu yomdwelisi.

Kwimo yokuSeta yokuQala, yiya kwiNdlela yoLawulo (CTrL) ipharamitha. Seta iparameter kwiProG. Cinezela INDEX kwiparamitha yokuHlela iPateni (PAtn). Sebenzisa iintolo ukukhetha ipateni oyifunayo ukuyihlela. Ngokucwangcisa iPateni yokuHlela iparamitha ukuba icime, ucinezela iqhosha le-INDEX lizisa iparamitha elandelayo kwimo yoSeto lokuQala. I-Ramp kunye nomsebenzi weSoak uxhaswa ziipateni ezi-8 ezahlukeneyo (amanani eepatheni 0 ukuya ku-7). Ipatheni nganye iqulethe amanyathelo angama-8 (amanani enyathelo 0 ukuya ku-7) ngexesha lokumisela kunye namaxesha okusebenza, ipharamitha yekhonkco enye (i-Linn) ipharamitha, ipharamitha yomjikelezo omnye (CyCn), kunye nepharamitha yenyathelo langempela (PSYn).

Ukungagqibeki kwenyathelo 0 kwipatheni 0 ngumsebenzi wokufunxa. Ulawulo kufuneka lucwangciswe ukufikelela kwi-Set Point (SV) ukushisa, i-X, emva kwexesha lokubulawa, T. Iyunithi iya kulawula ubushushu benkqubo (PV) ukufikelela kwiqondo lokushisa X kunye nokugcina ubushushu kwiqondo lokushisa X. Ixesha lokuphumeza i-T lichongwa lixesha lokubulawa (ti00) kwinombolo yesinyathelo 0. Indawo ekujoliswe kuyo (SP00) kwinombolo yesinyathelo se-0 kufuneka ilingane neqondo lokushisa le-XNUMX.

Emva kwenyathelo lokuqala, inkqubo SP01 kunye ne-ti01 ukuya kwi-SP07 kunye ne-ti07 yepateni yokuqala. Ixabiso lendawo ekujoliswe kuyo (SP0n) likwiyunithi yokwenyani kanye njengeNdawo yoSeti (SV). Ukuba ulawulo lusethelwe ubushushu, ke indawo ekujoliswe kuyo ibonise iqondo lobushushu. Ukuba ulawulo lucwangciselwe enye iyunithi yobunjineli, indawo ekujoliswe kuyo yokumisela imiboniso iya kusekwa kuloo yunithi. Ixesha lokuphunyezwa kwethagethi (ti0n) likwiiyunithi zexesha, (hh.mm). Imilinganiselo yenyathelo iya kulandelwa yiParameter yeNyathelo eyiyo, iparamitha yoMjikelo, kunye neparamitha yekhonkco yepateni nganye.

Eyona iNyathelo iparameter (PSYn) icwangcisa inyathelo lokugqibela eliphunyeziweyo kwipatheni yangoku. Umzekeloample, ukuba iNyathelo eyiyeyona iparameter imiselwe ku-2 kwipatheni 0, ngoko inkqubo iyakuqhuba kuphela amanyathelo 0, 1, kunye no-2 wepatheni 0.

Iparamitha yoMjikelo (CyCn) imisela ukuba mangaphi amaxesha ipateni yangoku iphindwaphindwa.

Umzekeloample, ukuba iparamitha yoMjikelo wepatheni 0 isetelwe ku-2, amanyathelo kwipatheni 0 aya kuphindwa kabini phambi kokuba udlulele kwipatheni elandelayo.

Unxulumaniso lweparamitha (Linn) yabela ipateni elandelayo yenkqubo ukuba iphunyezwe. Umzekeloample, ukuba iparameter yonxulumaniso imiselwe ku-3 kwipatheni 0, inkqubo iya kutsiba iipateni 1 no-2 kwaye iqalise ukwenza ipateni yesi-3 emva kwepateni engu-0 igqityiwe. Ukuba iParameter yekhonkco isetelwe ukuba iVAMILE, inkqubo iya kumisa emva kokuphumeza ipateni yangoku kwaye iqondo lobushushu liya kugcinwa kwindawo emiselweyo yenyathelo lokugqibela eliphunyeziweyo.

Ukubulawa

Ukuphunyezwa kwe-ramp kunye nesici sokufunxa siqaliswa ngokusebenzisa i-Run/Stop parameter, (rS) kwiNdlela yokuSebenza.

Iparamitha ye-Baleka/Yeka inamaxabiso anokwenzeka amane.

Ukuba i-Baleka/Yeka iparamitha imiselwe ku-run, inkqubo iyakuqala ukuphumeza ngolandelelwano ukusuka kwinyathelo lesi-0 lepatheni yokuqalisa.

Ukuba iParameter ye-Run/Stop icwangciswe kwiNkqubo yeSima (PStP), inkqubo iyakumisa kwaye igcine ubushushu bendawo yokugqibela phambi kokuba inkqubo imiswe. Xa iBaleka/Yemisa iparamitha iphinda iqalwe, inkqubo iya kuqalisa kwakhona kwaye iphumeze ukusuka kwinqanaba 0 lepatheni yokuqalisa.

Ukhetho lwepateni yokuqalisa (Ptrn) lufumaneka kuphela xa i-Far / Misa iparameter isetelwe kwiNkqubo yokuMisa.

Ukuba i-Fan/Misa iparameter imiselwe kuBamba lweNkqubo (PHD), inkqubo iza kunqunyanyiswa kwaye iqondo lobushushu lizakugcinwa kwindawo ebekiweyo yobushushu ebisebenzayo phambi kokuba inkqubo ibambe. Nje ukuba iparamitha ye-Run/Stop ibuyiselwe umva ukuba iqhube, inkqubo iya kulandela inyathelo phambi kokubamba kwaye iqalise ukuphumeza kuyo yonke inkqubo.

Bonisa

Ngexesha le-ramp kunye nokulawulwa kweprogram ye-soak, umboniso we-SV ongagqibekanga yi-P-XX, apho i-P ibonisa ipateni yokwenziwa yangoku kunye ne-XX ibonisa into yokubonisa i-Set Point Value (SP) okanye i-Residual Time (r-ti). Ixabiso leNdawo yokuSeta liza kubonisa iqondo lokuseta iqondo lobushushu lenyathelo langoku lokwenziwa kumboniso we-SV. Ixesha lokuHlala liza kubonisa ixesha eliseleyo lenyathelo langoku lokwenziwa kumboniso we-SV. Emva kokukhetha i-Seta yeXabiso leNdawo okanye iXesha leResidual, iqhosha elithi ENTER kufuneka licinezelwe ukuze lwamkele utshintsho olubonisayo.

INKQUBO NOKUSEBENZA KWE-PID

Ithiyori yokuSebenza

Indlela ye-PID yokulawula isekelwe kuhlengahlengiso lomntu ngamnye lwemilinganiselo yebhendi ehambelanayo, ixabiso lexesha elidibeneyo, kunye namaxabiso exesha eliphumayo ukunceda iyunithi ihlawule ngokuzenzekelayo utshintsho kwinkqubo yokulawula. Ibhendi yomlinganiselo luluhlu olujikeleze indawo emiselweyo apho ulungelelwaniso lolawulo lwenzeka khona. Ulawulo lunyusa okanye lunciphisa imveliso ngokulinganayo ukuya kuphambuko lwenkqubo yobushushu ukusuka kwindawo emiselweyo. Ixesha elidityanisiweyo liphelisa i-undershoot kunye ne-overshoot ye-set point ngokuhlengahlengisa ulawulo lokulinganisa ngokusekelwe kwisixa sokuphambuka ukusuka kwindawo emiselweyo ngexesha lokusebenza ngokuzinzile. Ixesha le-derivative liphelisa i-undershoot kunye ne-overshoot ngokulungelelanisa ulawulo lokulinganisa ngokusekelwe kwisantya sokunyuka okanye ukuwa kweqondo lokushisa. I-integrated deviation offset correction (ioFn) iphucula isantya apho ixabiso lenkqubo lifikelela kwixabiso lendawo emiselweyo.

Ukuba le parameter imiselwe ku-zero, imveliso iya kuba ngu-zero xa ixabiso lenkqubo lilingana nexabiso lendawo emiselweyo. Ukuba iparameter yexesha elidibeneyo isetyenziselwa kuphela ukuphelisa impazamo yesimo esizinzileyo, kunokuthatha ixesha elide ukufikelela kwindawo emiselweyo kuba ifuna ixesha lokuqokelela impazamo.

Le parameter ichaza umgangatho wemveliso omiselweyo ekuqaleni. Xa ixesha elidityanisiweyo limiselwe ku-0, ngoko ke i-proportional derivative offset correction (PdofF) iya kuthatha indawo yolungiso oludityanisiweyo lwe-offset, kodwa lusebenza umsebenzi ofanayo.

Ukuseta inkqubo

Ukuze usebenzise umsebenzi we-PID kubalawuli bechungechunge lwe-B, i-Mode yoLawulo kuya kufuneka ibekwe kwi-PID kwi-Itial Setting Menu. Emva kokutshintsha iNdlela yoLawulo, iiparamitha ze-PID zinokufumaneka kwiMenu yoLawulo. Iiparamitha ze-PID zinokucwangciswa ngesandla okanye zingasetwa ngumlawuli usebenzisa umsebenzi wokuguqula ngokuzenzekelayo. I-auto tune iyakusebenzisa uvavanyo kunye nemposiso ukutyumba iiparamitha ze-PID ukunika ulawulo olona lawulo luchanekileyo.

Ukusukela ukuba ixesha lokulungisa ngokuchanekileyo ulawulo lunokwahluka ngokuxhomekeke kwinkqubo, umlawuli unokucutshungulwa ngesandla kumaxabiso aziwayo e-PID ngaphambi kokuqhuba i-auto tune. Ukuqhuba/Misa iparameter kufuneka imiselwe ukusebenza ukuze kuqaliswe ukulungiswa okuzenzekelayo.

Umlawuli wechungechunge lwe-B unepro ezine ezichazwe ngumsebenzisifiles (PID0 ukuya kwi-PID3) yamaxabiso e-PID kunye nomsebenzi wokhetho oluzenzekelayo (PID4). Iseti nganye yamaxabiso e-PID ibandakanya ixabiso leengongoma ezimiselweyo (i-Svn), ibhendi yomlinganiselo (Pn), ixesha elidityanisiweyo (in), ixesha eliphuma kuyo (dn), kunye nokusetwa kokuphambuka okudityanisiweyo (iofn). Ukuba i-PID4 ikhethiwe, umlawuli uya kukhetha ukuba leliphi iqela lomsebenzisi elichaziweyo iparameters ukuba lisetyenziswe ngokusekelwe kwindlela ekufutshane ngayo ixabiso lendawo yokumisela yepro.file ikwixabiso lenkqubo yangoku.

INGCACISO YEMENU STRUCTURE

Udweliso lwenkqubo lomlawuli lwahlulahlulwe lube ziimenyu ezintathu (Ukusebenza, ukuLawulwa, kunye nokuSekwa kokuQala). Ekusebenzeni okuqhelekileyo, ulawulo luya kuba kwi-Operation Menu.

IMENU YOKUSEBENZA

Ukucofa iqhosha le-INDEX liza kujikeleza le miba yemenyu ingezantsi. Ipharamitha iya kuboniswa kwisiboniso esiphezulu, ngelixa ixabiso layo liza kuboniswa kwisiboniso esisezantsi, ngaphandle kwendawo yokumisela eboniswa kwisiboniso esisezantsi kwiSiboniso saseKhaya. I-UP kunye ne-PHANSI amatolo atshintsha amaxabiso eparameters. Iqhosha elithi ENTER kufuneka licofe emva kwalo naluphi na utshintsho.

| Lungisa ixabiso leengongoma ezimiselweyo - Ingaba naliphi na ixabiso lamanani phakathi komda ophezulu kunye nophantsi woluhlu lweqondo lokushisa. | |

| Khetha u-Baleka – Misa uLawulo lweZiphumo. Yenza iziphumo zisebenze kwaye iQalisa i-Ramp/Zalisa. Yekisa ukusebenza iziphumo kwaye Ukumisa Ramp/Zalisa. Iyamisa Ramp/Inkqubo yeSoak, iziphumo zihlala zisebenza. Ifumaneka kuphela ngexesha ramp/ukusebenza ngokumanzisa. Inkqubo iqala kwakhona kwiNyathelo lesi-0 lePhatheni yokuQalisa. |

|

| Unqumama Ramp/Inkqubo yeSoak, iziphumo zihlala zisebenza. Ifumaneka kuphela ngexesha ramp/ukusebenza ngokumanzisa. Inkqubo iqala kwakhona kwinqanaba phambi kokuba kubanjwe inkqubo. |

|

| Seta ipateni yokuQala ye-Ramp/Zalisa. Ifumaneka kuphela xa r – S imiselwe kwi-PSTP. | |

| Inani lamasuntswana ekunene kwedesimali. I-Decimal PointPosition inokusetwa kuwo onke amaNgeniso ngaphandle kohlobo lwe-B, S, no-R thermocouples. |

|

| I-Alamu yoku-1 ePhakamileyo yokuSeta indawo. Isenokungabonakali ngokuxhomekeke kwi-ALA1 yokucwangcisa kwi-Initial Setting Menu. | |

| I-Alarm 1 Indawo yokuSeta ePhantsi. Isenokungabonakali ngokuxhomekeke kwi-ALA1 yokucwangcisa kwi-Initial Setting Menu. | |

| I-Alamu yesi-2 ePhakamileyo yokuSeta indawo. Isenokungaveli ngokuxhomekeke kwi-ALA2 yokucwangcisa kwi-Initial Setting Menu. | |

| I-Alarm 2 Indawo yokuSeta ePhantsi. Isenokungabonakali ngokuxhomekeke kwi-ALA2 yokucwangcisa kwi-Initial Setting Menu. | |

| I-Alamu yesi-3 ePhakamileyo yokuSeta indawo. Isenokungaveli ngokuxhomekeke kwi-ALA3 yokucwangcisa kwi-Initial Setting Menu. | |

| I-Alarm 3 Indawo yokuSeta ePhantsi. Isenokungabonakali ngokuxhomekeke kwi-ALA3 yokucwangcisa kwi-Initial Setting Menu. | |

| Seta isitshixo sokhuseleko sephaneli yangaphambili. | |

| Tshixa zonke iisetingi. | |

| Tshixa zonke iisetingi ngaphandle kwendawo emiselweyo. | |

| Bonisa i-% ixabiso lemveliso ye-1. Kwimo yesandla, eli xabiso linokutshintshwa ngokusebenzisa iintolo eziphezulu nasezantsi. | |

| Bonisa i-% ixabiso lemveliso ye-2. Kwimo yesandla, eli xabiso linokutshintshwa ngokusebenzisa iintolo eziphezulu nasezantsi. |

UMGAQO MENU

Cofa iqhosha elithi ENTER ngelixa ukwiSiboniso saseKhaya ukuze ufikelele kwiMenu yoMiselo.

Ukucofa iqhosha le-INDEX liza kujikeleza le miba yemenyu ingezantsi. Ipharamitha iya kuboniswa kwisiboniso esiphezulu, ngelixa ixabiso layo liya kuboniswa kwisiboniso esisezantsi. I-UP kunye ne-PHANSI amatolo atshintsha amaxabiso eparameters. Iqhosha elithi ENTER kufuneka licofe emva kwalo naluphi na utshintsho.

| Tune ngokuzenzekela. Umlawuli uya kuvavanya inkqubo kwaye ukhethe amaxabiso e-PID ukugcina ulawulo oluhle. Ifumaneka kuphela xa imo yolawulo isetelwe kwi-PID. | |

| Qala ukufunda inkqubo. Emva kokuba inkqubo ifundiwe imenyu iya kubuyela ku-OFF. | |

| Khubaza iTune ezenzekelayo. | |

| Ukukhethwa kwePID profile. Umlawuli unokugcina ukuya kuthi ga kwi-4 PID profiles. Umboniso ophezulu uya kubonisa iPID profile kwaye i umboniso osezantsi uzakubonisa ixabiso lenjongo ebekiweyo yalo profile. Xa iPid4 ikhethiwe, umlawuli uya kukhetha ngokuzenzekelayo yeyiphi iPID profile ukusebenzisa ngokusekelwe kumaxabiso ekujoliswe kuwo. Ifumaneka kuphela xa imo yolawulo imiselwe kwi-PID. Jonga iNkqubo kunye nokusebenza komsebenzi wePID ngolwazi oluthe kratya. (n = 0 ukuya ku-4) |

|

| Ixabiso lokuSeta ekujoliswe kulo elinxulumene nePID Pro nganyefile. (n = 0 ukuya ku-3). | |

| ULungiso lwebhendi elinganayo ehambelana nePID Pro nganyefile. (n =0 ukuya kwisi-3). | |

| Ixesha elidibeneyo (ixesha lokusetha kwakhona) elihambelana nePID Pro nganyefile. (n = 0 ukuya ku-3). | |

| Ixesha eliphumayo (ixesha lokulinganisa) elihambelana nePID Pro nganyefile. (n = 0 – 3). | |

| ULungelo oluDibeneyo lweDeviation Offset ehambelana nePID Pro nganyefile. (n = 0 ukuya ku-4) |

| PD Offset Ulungiso loLungiso. ifumaneka kuphela xa imo yolawulo imiselwe kwi-PID kunye nexesha elidityanisiweyo = 0. Jonga iNkqubo kunye nokusebenza komsebenzi wePID wokuhambisa ulwazi. |

|

| Ukufudumeza i-Hysteresis (Ukwahluka) Ukuseta. Icwangcisa ixabiso lobungakanani bomahluko phakathi kwendawo yokucima (indawo yokubeka) kunye nendawo yokuvula. Umzobo A ubonisa ukuziphatha kwemveliso yesicelo sokufudumeza (ukubuyisela umva). Ifumaneka kuphela xa imo yolawulo isetelwe ku-/off control. |

|

| Ukupholisa i-Hysteresis (Ukwahluka) Ukuseta. Icwangcisa ixabiso lobungakanani bomahluko phakathi kwendawo yokucima (indawo yokubeka) kunye nendawo yokuvula. Umzobo A ubonisa ukuziphatha kwemveliso yesicelo sokupholisa (esenza ngokuthe ngqo). Ifumaneka kuphela xa imo yolawulo isetilwe ku-on/off control. |

Umzobo A: Ukuziphatha kwemveliso yoKufudumeza / Ukupholisa kwi-Applications

| UkuSetwa koMjikelo wokuFundisa. Ichaza ubude bexesha lemveliso enye okanye umjikelo wemveliso 1. Ifumaneka kuphela xa ulawulo imowudi isetelwe kwi-PID okanye iProG kwaye Imveliso 1 isetelwe ukufudumeza. |

|

| UkuSetwa koMjikelo woLawulo lokuPholisa. Ichaza ubude bexesha lemveliso enye okanye umjikelo wemveliso 1. Ifumaneka kuphela xa ulawulo imowudi isetelwe kwi-PID okanye iProG kwaye Imveliso 1 isetelwe ukupholisa. |

|

| Ukusetwa koMjikelo wokuLawula kwimveliso 2. Ichaza ubude bexesha elinye lemveliso okanye umjikelo wemveliso 2. Ifumaneka kuphela xa imo yolawulo imiselwe kwi-PID kunye noLawulo lokuPhuma kweLuphu eDual. | |

| I-Proportional Band Coefficient. Iseta ixabiso lebhendi yomlinganiselo wemveliso 2. Ibhendi elinganayo yemveliso 2 ilingana nebhendi elinganayo yemveliso 1 ephindwe nge-proportional band coefficient. Le parameter ifumaneka kuphela xa imo yolawulo isetelwe kwi-PID kunye noLawulo lokuPhuma kweLuphu eDual. | |

| Dead Band. Ummandla ugxile kwindawo yokumisela apho ulawulo lucingelwa ukuba lukwinqanaba elifunekayo. Iziphumo ziya kucinywa kweli nqanaba ngaphandle kokuba kukho ukutenxa okudityanisiweyo okanye ibhendi efileyo inegative. Le parameter iboniswa kuphela xa ulawulo lusetelwe kuLawulo lweZiphumo zeLuphu ezimbini. |

Ukusebenza kwemveliso yokulawula i-ON / OFF ngexesha lolawulo lwemveliso ye-loop ezimbini.

Umzobo B: Ukusebenza kwemveliso ngexesha lolawulo lwe-loop ezimbini

| Inkqubo yoHlengahlengiso lobushushu. Eli nqaku livumela ixabiso legalelo ukuba litshintshwe ukuze livumelane nereferensi yangaphandle okanye ukubuyisela imposiso yoluvo. | |

| I-Analog Output High Limit: Icwangcisa owona mda ophezulu wemveliso ye-analog xa imveliso yolawulo isebenza kwi-100%. Ifumaneka kuphela kwiimodeli zemveliso ye-analog. |

|

| IsiPhumo se-Analog ephantsi. Icwangcisa owona mda osezantsi wemveliso ye-analog xa imveliso yolawulo isebenza kwi-0%. Ifumaneka kuphela kwiimodeli zemveliso ye-analog. |

IMENU YOKUSETYENZISWA YOKUQALA

Cofa kwaye ubambe iqhosha elithi ENTER ubuncinci imizuzwana emi-3 ngelixa ukwiSiboniso saseKhaya ukuze ufikelele kwiMenyu yoSeto lokuQala. Ukucofa iqhosha le-INDEX liza kujikeleza le miba yemenyu ingezantsi. Ipharamitha iya kuboniswa kwisiboniso esiphezulu, ngelixa ixabiso layo liya kuboniswa kwisiboniso esisezantsi. I-UP kunye ne-PHANSI amatolo atshintsha amaxabiso eparameters. Iqhosha elithi ENTER kufuneka licofe emva kwalo naluphi na utshintsho.

| Ukhetho Lwegalelo. Khetha enye yezi ntlobo zegalelo zilandelayo kwitheyibhile engezantsi. Ngamagalelo angoku, i-250 Ohm Resistor kufuneka zifakwe kwiiterminal zongeniso. |

| Uhlobo Loluvo Loluvo Lobushushu | Umboniso we-LED | Uluhlu lobushushu |

| Uhlobo lwe-Thermocouple TXK | -328 ~ 1472°F (-200 ~ 800°C) | |

| Uhlobo lwe-Thermocouple U | -328 ~ 932°F (-200 ~ 500°C) | |

| Uhlobo lwe-Thermocouple L | -328 ~ 1562°F (-200 ~ 850°C) | |

| Uhlobo lwe-Thermocouple B | 212 ~ 3272°F (100 ~ 1800°C) | |

| Uhlobo lwe-Thermocouple S | 32 ~ 3092°F (0 ~ 1700°C) | |

| Uhlobo lwe-Thermocouple R | 32 ~ 3092°F (0 ~ 1700°C) | |

| Uhlobo lwe-Thermocouple N | -328 ~ 2372°F (-200 ~ 1300°C) | |

| Uhlobo lwe-Thermocouple E | 32 ~ 1112°F (0 ~ 600°C) | |

| Uhlobo lwe-Thermocouple T | -328 ~ 752°F (-200 ~ 400°C) | |

| Uhlobo lwe-Thermocouple J | -148 ~ 2192°F (-100 ~ 1200°C) | |

| Uhlobo lwe-Thermocouple K | -328 ~ 2372°F (-200 ~ 1300°C) | |

| I-Platinum Resistance (Pt100) | -328 ~ 1112°F (-200 ~ 600°C) | |

| I-Platinum Resistance (JPt100) | -4 ~ 752°F (-20 ~ 400°C) | |

| 0 ~ 50mV Igalelo leAnalog | -999 ~ 9999 | |

| 0V ~ 10V Igalelo leAnalog | -999 ~ 9999 | |

| 0V ~ 5V Igalelo leAnalog | -999 ~ 9999 | |

| 4 ~ 20mA Igalelo leAnalog | -999 ~ 9999 | |

| 0 ~ 20mA Igalelo leAnalog | -999 ~ 9999 |

| Imo Yokulawula. Khetha indlela yokusebenza yokulawula. Inokusetwa kwi-PID, i-Off, Manual, okanye i-Ramp/Soak inkqubo. | |

| Ramp/UKhetho lwePatheni yokuSoka. Ivumela umsebenzisi ukuba akhethe ukuba yeyiphi kwi-8 ramp/ faka iipateni kwiprogram. Ipateni nganye inamanyathelo asi-8 anika isimbuku samanyathelo angama-64 anokwenzeka kwinkqubo enye. Xa igqityiwe inkqubo yonke ramp kunye neepateni zokucwina, iparameter kufuneka imiselwe. (n = 0 ukuya kwisi-7) | |

| Icandelo leSeti yeNdawo yepateni n kunye nenyathelo y. UmzekeloampLe inyathelo lokuqala lepateni yokuqala iya kuba yi-SP00. Inyathelo lokugqibela liya kuba SP77. (n = 0 ukuya ku-7, y = 0 ukuya ku-7) |

|

| Icandelo Ixesha lepateni n kunye nenyathelo y. Umzekeloampinyathelo lokuqala lepatheni yokuqala iya kuba yi-ti00. Inyathelo lokugqibela liya kuba nguTi77. Ixabiso lale parameter izakuba kwi HH:MM. (n = 0 ukuya ku-7, y = 0 ukuya ku-7) |

|

| Inyathelo lokugqibela lepateni n. Icwangcisa inyathelo lokugqibela eliza kwenziwa kwipatheni yangoku. (n = 0 ukuya kwisi-7) | |

| Umiselo lwePateni yeLoop yomfuziselo n. Icwangcisa inani lamaxesha apho ipateni yangoku iza kuphindwa. (n = 0 ukuya kwisi-7) | |

| Ikhonkco lepateni yepateni n. Icwangcisa ipateni elandelayo eza kwenziwa emva kwepateni yangoku. Xa ivaliwe, inkqubo iya kuphela kwaye igcine indawo yokugqibela yokuseta. (n = ukuya kwisi-7) | |

| Ukukhetha Ubushushu/okupholileyo. Inika imveliso 1 kunye nemveliso 2 ukuba ibe bubushushu okanye ipholile. UBUSHUSHU = Imveliso 1 = Ukufudumeza CoolL = Imveliso 1 = Ukupholisa H1C2 = Imveliso 1 = Ukufudumeza; Imveliso 2 = Ukupholisa H2C1 = Imveliso 1 = Ukupholisa; Imveliso 2 = Ukufudumeza |

|

| I-alam 1 Ukuseta. Iseta ukusebenza kweAlam 1. Nceda ujonge okukhethiweyo kwiZiphumo zeAlam ngenkcazelo yeziphumo. | |

| I-alam 2 Ukuseta. Iseta ukusebenza kweAlam 2. Nceda ujonge okukhethiweyo kwiZiphumo zeAlam ngenkcazelo yeziphumo. | |

| I-alam 3 Ukuseta. Iseta ukusebenza kweAlam 3. Nceda ujonge okukhethiweyo kwiZiphumo zeAlam ngenkcazelo yeziphumo. (ayifumaneki kuLawulo lweZiphumo eziLungelele kabini) |

|

| Inkqubo yokumisela iAlarm. Ikhetha ukuba yeyiphi imveliso ye-alam esetyenziswayo ukuba isivusi senkqubo senzeka. Iialamu zesistim ziya kuba yimpazamo yegalelo okanye ukusilela kolawulo lwenkqubo. Olu phawu lunokuvalwa ngokujika le parameter ukuba icime. | |

| UNxibelelwano Bhala iFunction Feature. Ivumela iiparamitha ukuba zitshintshwe ngonxibelelwano lwe-RS-485. Ukuseta OFF kuthintela naluphi na utshintsho olusuka kubasebenzisi abakude. | |

| Ukhetho lweProtocol: Khetha ukuba unxibelelane na usebenzisa i-ASCII okanye i-RTU Protocol. Eli xabiso kufuneka lingqinelane nenkqubo esetyenziswa ngumamkeli ikhompyutha. |

|

| Idilesi yoMlawuli: Misela ukusuka ku-1 ukuya ku-247. Eli xabiso kufuneka lihambelane nedilesi yomlawuli esetyenziswa yikhompyutha ebamba umkhosi. | |

| Ubude beDatha yoNxibelelwano. Khetha nokuba yi-7 okanye 8. Eli xabiso kufuneka lihambelane nobude bedatha yonxibelelwano lwekhompyuter yenginginya. | |

| Unxibelelwano lweParity Bit. Cwangcisa eli xabiso ukuba lilingane, umnqakathi, okanye akukho nanye. Eli xabiso kufuneka lihambelane nentwana yonxibelelwano yekhompyuter yenginginya. |

|

| Unxibelelwano Stop Bit. Cwangcisa eli xabiso ukuya ku-1 okanye ku-2. |

Ulungelelwaniso lweMphumo yeAlam kunye neTheyibhile yokuSebenza.

| Seta ixabiso | Uhlobo lweAlarm | Ukusebenza kweAlarm Output |

| 1 | Umsebenzi we-alam uvaliwe | Imveliso CIMA |

| Ukutenxa kumda ophezulu- nasezantsi: Esi siphumo se-alam sisebenza xa ixabiso le-PV liphezulu kunexabiso lokucwangcisa i-SV+(AL-H) okanye lisezantsi kunexabiso lokucwangcisa SV-(AL-L). |

||

| 2 | Ukutenxa umda ongaphezulu: Esi siphumo se-alamu sisebenza xa ixabiso le-PV liphezulu kunexabiso lokumisela i-SV+ (AL-H). |

|

| 3 | Ukutenxa kumda osezantsi: Esi siphumo se-alam sisebenza xa ixabiso le-PV lingaphantsi kunexabiso lokucwangcisa i-SV-(AL-L). |

|

| 4 | Ukutenxa umva phezulu- nasezantsi-umda: Esi siphumo se-alamu sisebenza xa ixabiso le-PV likuluhlu lwexabiso lokucwangcisa i-SV+ (AL-H) kunye nexabiso lokucwangcisa SV-(AL-L). |

|

| 5 | Ixabiso elipheleleyo phezulu- nasezantsi-umda: Esi siphumo se-alamu sisebenza xa ixabiso le-PV liphezulu kunexabiso lokumisela i-AL-H okanye liphantsi kunexabiso lokumisela i-AL-L. |

|

| 6 | Ixabiso elipheleleyo elingaphezulu komda: Le mveliso ye-alamu isebenza xa ixabiso le-PV liphezulu kunexabiso lokumisela i-AL-H. |

|

| 7 | Ixabiso elipheleleyo lisezantsi kumda: Esi siphumo se-alam sisebenza xa ixabiso le-PV lingaphantsi kwexabiso lokumisela AL-L. |

|

| 8 | Ukutenxa kumda ophezulu- nasezantsi ngolandelelwano lokulinda: Esi siphumo se-alam sisebenza xa ixabiso le-PV lifikelela kwindawo yokubeka (ixabiso le-SV) kwaye ixabiso liphezulu kunexabiso lokucwangcisa i-SV+(AL-H) okanye lisezantsi kunexabiso lokucwangcisa SV-(AL-L). |

|

| 9 | Ukutenxa umda ophezulu ngolandelelwano lokulinda: Esi siphumo se-alamu sisebenza xa ixabiso le-PV lifikelela kwindawo yokumisela (ixabiso le-SV) kwaye ixabiso elifikelelekayo liphezulu kunexabiso lokumisela i-SV + (AL-H). |

|

| 10 | Ukutenxa umda osezantsi ngolandelelwano lokulinda: Esi siphumo se-alamu sisebenza xa ixabiso le-PV lifikelela kwindawo yokumisela (ixabiso le-SV) kwaye ixabiso elifikelelweyo lingaphantsi kwexabiso lokucwangcisa i-SV-(AL-L). |

|

| 11 | Imveliso ye-alam yomda we-Hysteresis ephezulu: Esi siphumo se-alam sisebenza ukuba ixabiso le-PV liphezulu kunexabiso lokusetha i-SV+ (AL-H). Le mveliso ye-alam IYAVALWA xa ixabiso lePV lingaphantsi kwexabiso lokucwangcisa SV+(AL-L). |

|

| 12 | Imveliso ye-alam yomda osezantsi weHysteresis: Le mveliso ye-alam isebenza ukuba ixabiso le-PV lingaphantsi kwexabiso lokucwangcisa i-SV-(AL-H). Esi siphumo se-alam IYAVALWA xa ixabiso le-PV liphezulu kunexabiso lokumisela SV-(AL-L). |

|

| 13 | Imveliso ye-alam ye-CT: Le alamu isebenza xa i-current ilinganiswe yi-transformer (CT) iphantsi kwe-AL-L okanye iphezulu kune-AL-H (Le mveliso ye-alarm ifumaneka kuphela kumlawuli kunye ne-transformer yangoku). |

|

| 14 | Xa ulawulo lwenkqubo lukwimo yesiphelo, ukuphuma kwe-alam IVULIWE. | |

| 15 | Xa uRAMP Isimo se-UP senzeka kulawulo lwenkqubo ye-PID, ukuphuma kwe-alarm KUVULIWE. | |

| 16 | Xa uRAMP Imeko PHANTSI yenzeka kulawulo lwenkqubo ye-PID, ukuphuma kwe-alarm KUVULIWE. | |

| 17 | Xa imeko ye-SOAK isenzeka kulawulo lwenkqubo ye-PID, ukuphuma kwe-alarm KUVULIWE. | |

| 18 | Xa imeko ye-RUN isenzeka kulawulo lwenkqubo ye-PID, ukuphuma kwe-alam KUVULIWE. |

( Phawula: I-AL-H kunye ne-AL-L ziquka i-AL1H, AL2H, AL3H kunye ne-AL1L, AL2L, AL3L)

ULuhlu lweerejista zoNxibelelwano

- Ukuxhasa isantya sothumelo: 2400, 4800, 9600, 19200, 38400 bps.

- Iifomati ezingaxhaswanga: 7, N, 1 okanye 8, O, 2 okanye 8, E, 2.

- Iprotocol yonxibelelwano: Imodus (ASCII okanye RTU).

- Ikhowudi yomsebenzi: 03H ukufunda imixholo yerejista (Max. 8 amagama). 06H ukubhala igama eli-1 (enye) kwirejista. 02H ukufunda iibits data (Max. 16 bits). 05H ukubhala ibhithi e-1 (enye) kwirejista.

- Idilesi kunye nesiqulatho seRejista yeDatha:

Idilesi Umxholo Ingcaciso 1000H Ixabiso lenkqubo (PV) Iyunithi yokulinganisa yi-0.1, ihlaziywa ngexesha elinye kwi-0.4 yesibini. Umboniso wexabiso lokufunda ulandelayo ubonisa impazamo eyenzekayo: 8002H : Inkqubo yokuqala (Ixabiso lobushushu alikafiki) 8003H : Uluvo lobushushu aludityaniswanga

8004H : Impazamo yokufaka isivamvo sobushushu

8006H : Ayinakufumana ixabiso lobushushu, impazamo yegalelo le-ADC 8007H: Impazamo yokufunda/yokubhala1001H Seta indawo (SV) Iyunithi yi-0.1, oC okanye ye 1002H Umda ophezulu woluhlu lobushushu Umxholo wedatha akufanele ube phezulu kunoluhlu lobushushu 1003H Umda osezantsi woluhlu lobushushu Umxholo wedatha akufanele ube ngaphantsi kweqondo lokushisa 1004H Uhlobo loluvo lobushushu boluvo kunye noHlelo loBubushushu” ngeenkcukacha Nceda ujonge imixholo “yeNxibelelaniso yeqondo lobushushu 1005H Indlela yokulawula 0: PID, 1: VULA/OFF, 2: ulungelelwaniso lwezandla, 3: Ulawulo lwenkqubo yePID 1006H Ukufudumeza / Ukupholisa ukhetho lolawulo 0: Ukufudumeza, 1: Ukupholisa, 2: Ukufudumeza/Ukupholisa, 3: Ukupholisa/Ukufudumeza 1007H Iqela loku-1 loMjikelo wokulawula ukuFudumeza/Ukupholisa 0-99, 0:0.5 umzuzwana 1008H Iqela le-2 loMjikelo wokulawula Ukufudumeza / Ukupholisa 0-99, 0:0.5 umzuzwana 1009H Ibhendi yePB ngokomlinganiselo 0.1 – 999.9 100AH Ixesha elibalulekileyo 0-9999 I-100BH Td Ixesha eliphumayo 0-9999 100CH Ukudityaniswa okumiselweyo 0-100%, iyunithi yi-0.1% 100DH Ixabiso lemposiso yokulawula ngokulinganayo, xa Ti = 0 0-100%, iyunithi yi-0.1% 100EH Ukusetwa kwe-COEF xa kusetyenziswa ulawulo lwemveliso ye-Dual Loop 0.01 – 99.99 100FH Ukusetwa kwe-Dead band xa ulawulo lwemveliso yeDual Loop lusetyenziswa -999 - 9999 1010H Ixabiso lokumisela i-Hysteresis yeqela le-1 lemveliso 0 – 9999 1011H Ixabiso lokumisela i-Hysteresis yeqela le-2 lemveliso 0 – 9999 1012H Ixabiso lemveliso lifundeka kwaye libhalwe kwiMowudi yoku-1 kuphela. Iyunithi yi-0.1%, umsebenzi wokubhala uyasebenza phantsi kolungiso lwezandla 1013H Ixabiso lemveliso lifundeka kwaye libhalwe kwiMowudi yoku-2 kuphela. Iyunithi yi-0.1%, umsebenzi wokubhala uyasebenza phantsi kolungiso lwezandla 1014H Ulawulo oluphezulu lwe-analog linear output IYunithi e-1 = 2.8uA(Isiphumo Sangoku)=1.3mV(I-Lirear Voltage Isiphumo) 1015H Umda osezantsi wolawulo lwemveliso yomgca we-analog IYunithi e-1 = 2.8uA(Isiphumo Sangoku)=1.3mV(I-Lirear Voltage Isiphumo) 1016H Ixabiso lolawulo lobushushu -999-+999, iyunithi: 0.1 1017H Ummiselo wokugqibela we-analog 0 – 3 101CH Ukukhetha ipharamitha yePIO 0-4 101DH Ixabiso le-SV lihambelana nexabiso le-PID Isebenza kuphela kuluhlu olukhoyo, iyunithi: isikali se-0.1 1020H I-alam 1 uhlobo Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 1021H I-alam 2 uhlobo Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 1022H I-alam 3 uhlobo Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 1023H Ukusetha i-alam yenkqubo 0 : Akukho nanye (ehlala ikho), 1-3 : Seta iAlam 1 ukuya kwiAlam 3 1024H I-alam yomda ongaphezulu 1 Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 1025H I-alam yomda osezantsi 1 Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 1026H I-alam yomda ongaphezulu 2 Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 1027H I-alam yomda osezantsi 2 Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 1028H I-alam yomda ongaphezulu 3 Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 1029H I-alam yomda osezantsi 3 Nceda ujonge imixholo ye "Alarm Outputs" ngeenkcukacha 102AH Funda ubume be-LED b0 : Alm3, b1: Alm2, b2: F, b3: _, b4: Alm1, b5: OUT2, b6: OUT1, b7: AT I-102BH Funda ubume beqhosha lokutyhala b0 : Seta, b1 : Khetha, b2 : Phezulu, b3 : Phantsi. 0 kukutyhala 102CH Ukuseta imo yokutshixa 0 : Eqhelekileyo, 1 : Zonke izicwangciso zokutshixa, 11 : Tshixa ezinye kunexabiso le-SV 102FH Uguqulelo lwesoftware I-V1.00 ibonisa i-Ox100 1030H Inombolo yepateni yokuqala 0 – 7 1040H- 1047H Olona cwangciso lwenombolo yenyathelo ngaphakathi kwepateni ehambelanayo inyathelo N 0 – 7 = N, bonisa ukuba le pateni iphunyeziwe ukusuka kwinqanaba 0 ukuya 1050H- 1057H Inombolo yomjikelezo wokuphinda ukuphunyezwa kwepateni ehambelanayo I-0 - 99 ibonisa ukuba le pateni yenziwe ngamaxesha angama-1-100 1060H- 1067H Isetingi senani lepatheni yekhonkco lepateni ehambelanayo I-0 - 8, 8 ibonisa ukuphela kweprogram. I-0-7 ibonisa inombolo yepatheni elandelayo emva kokwenza ipatheni yangoku 2000H-203FH Ipateni 0-7 iqondo lobushushu iseti inqaku isicwangciso Ipateni 0 lobushushu imiselwe 2000H-2007H -999 - 9999 2080H- 20BFH Umzekelo 0-7 wokwenziwa kwexesha ucwangcisa Ipateni 0 ixesha limiselwe 2080H-2087H Ixesha 0 - 900 (1 umzuzu kwisikali ngasinye) - Idilesi kunye noMxholo weBit Register: (Intwana yokuqala yokufunda iya kufakwa kwi-LSB, Bhala idatha = FF00H ye-bit set, 0000H ukuze icace kancinci)

| Idilesi | Umxholo | Ingcaciso |

| 0811H 0810H 0813H 0812H 0814H 0815H 0816H |

Ukhetho lokubonisa iyunithi yobushushu Ukukhetha ukubhala konxibelelwano AT setting Ukukhetha indawo yedesimali Lawula REN/YIMA useto MISA useto lolawulo lwenkqubo yePID YIMA okwethutyana kulawulo lwenkqubo ye-PID |

Unxibelelwano bhala ngokukhubazekileyo: 0 (ehlala ikho), Unxibelelwano bhala luvuliwe: 1 oC / igalelo lomgca (okuhlala kukho) : 1 , ye: 0 Ngaphandle kohlobo lwe-thermocouple B, S, R, zonke ezinye iintlobo ze-thermocouple ziyasebenza. (0 okanye 1) CIMA: 0 (okuhlala kukho), VULA: 1 0 : YIMA, 1 : QHUBEKA (okuhlala kukho) 0: QAPHELA (okungagqibekanga), 1: YIMA 0: QAPHELA (okungagqibekanga), 1: YIMA okwethutyana |

IMIYALEZO YEMPASO YOKUFUMANA

Bonisa Imiyalezo Yemposiso

| Bonisa | Inkcazo | Kufuneka Inyathelo | |

| PV | b150 | Bonisa kwi-Start Up | Akukho nyathelo lifunekayo |

| SV | rr | ||

| PV | Hayi | Alukho uQhakamshelwano lweProbe yoNgeniso | Qinisekisa ukuba isivamvo soluvo sifakwe kwiiterminal ezifanelekileyo. Okulandelayo, khangela ukuba isilawuli sicwangciswe ngohlobo oluchanekileyo lwegalelo. Uninzi lubonwa xa isilawuli sicwangciselwe i-RTD, ngelixa i-thermocouple iqhagamshelwe. |

| SV | Qhuba | ||

| PV | Impazamo | Imposiso yoNgeniso | Qinisekisa ukuba igalelo lifakwe kwiintambo ezifanelekileyo. Jonga kwakhona ukuze ubone ukuba uhlobo lwegalelo lusetelwe kwixabiso elifanelekileyo. Uninzi oluqhelekileyo lubonwa xa isilawuli silungiselelwe igalelo le-4 ukuya kwi-20 mA kunye ne-0 ukuya kwi-20 mA isignali ifakwe kumlawuli. |

| SV | kwiPt | ||

| PV | 2001 | Ixabiso Lenkqubo Iyakhanya xa ingaphandle koluhlu | Imiqondiso yokufaka iqhele ukuya ngaphezulu okanye ngaphantsi koluhlu lwemida. Ukuba awukhangeli igalelo kwaye ulungise ubushushu benkqubo okanye ukwandise imida yoluhlu lweqondo lokushisa usebenzisa i-tP-H kunye ne-tP-L. |

| SV | 0.0 | ||

| PV | Impazamo | Imposiso EEPROM | Zama ukuseta ngokutsha useto olumiselweyo lwasefektri usebenzisa imiyalelo ekwicandelo elilandelayo. Ukuba kusenempazamo, fowunela inkonzo yabathengi ngenombolo yogunyaziso lwempahla ebuyayo ukuze umlawuli avavanywe kumzi-mveliso. |

| SV | Ipron | ||

Imiyalezo yemposiso yoNxibelelwano

| Imeko yempazamo 102EH/4750H | I-PV ifunde umva 1000H/4700H | Isimo sempazamo |

| 0001H | N / A | I-PV ayizinzanga |

| 0002H | 8002H | Phinda uqalise, akukho bushushu ngeli xesha |

| 0003H | 8003H | Uluvo loluvo khange luqhagamshelane |

| 0004H | 8004H | Imposiso yoNgeniso loMqondiso |

| 0005H | N / A | Ngaphezulu koLunge loNgeniso |

| 0006H | 8006H | I-ADC iyasilela |

| 0007H | N / A | EEPROM impazamo yokufunda/yokubhala |

Seta kwakhona imimiselo eMiselweyo yeFactory

Phawula: Ukuseta kwakhona Useto oluMiselweyo lweFactory kucima onke amaxabiso afakwe ngumsebenzisi. Rekhoda naziphi na iisetingi eziyimfuneko phambi kokuba uqhubeke.

Isilumkiso: Ukucima amaxabiso afakiweyo umsebenzisi kunokubangela ingozi yokhuseleko kunye nokungasebenzi kakuhle kwenkqubo.

Le miyalelo ilandelayo iya kusetha kwakhona isilawuli kwiseto yoqobo yasefektri.

Inyathelo 1. Cofa i-INDEX KEY ngelixa ukwiSiboniso saseKhaya de umlawuli afunde i-LoC kumboniso wenkqubo. Sebenzisa utolo oluPhezulu ukukhetha i-LoC1. Cofa i-ENTER KEY ukugcina eli xabiso.

Inyathelo lesi-2. Cofa kwaye ubambe utolo oluthi PHEZULU PHANSI ngaxeshanye umzuzwana omnye. Emva kokukhulula amaqhosha, umboniso uya kufunda i-SHOu kwi-PV display kunye ne-OFF kwisibonisi se-SV.

Inyathelo 3. Cinezela iqhosha le-INDEX kanye kwaye umlawuli uya kufunda i-PASS kwi-PV display kunye ne-4321 kwisibonisi se-SV. Lungisa ixabiso kumboniso we-SV ukuya ku-1357 usebenzisa i-UP kunye ne-PHANSI. Cofa i-ENTER KEY ukugcina ixabiso.

Inyathelo 4. Biyela amandla kumlawuli. Ekunyusweni kwamandla, onke amaxabiso aseti yomsebenzisi acinyiwe.

INGCACISO

| Igalelo Voltage | 100 ukuya 240 VAC 50/60 Hz OKANYE 24 VDC (kuxhomekeke imodeli) |

| Umsebenzi weVoltagUluhlu | I-85% ukuya kwi-110% yomthamo olinganisiweyotage. |

| Ukutya umbane | 5VA ubuninzi. |

| Ukukhuselwa kweMemori | I-EEPROM 4K bit (imemori engaguqukiyo (inani lokubhala: 1000,000)). |

| Indlela yokubonisa | Umgca we-2 x 4 umlingiswa we-7-segment ye-LED umboniso Ixabiso lenkqubo (PV): Umbala obomvu, Beka iphoyinti (SV): Umbala oluhlaza. |

| Uhlobo Lwenzwa | Thermocouple: K, J, T, E, N, R, S, B, L, U, TXK. |

| Iplatinam ye-RTD ye-3: Pt100, JPt100. | |

| Igalelo le-Analog 0 ukuya ku-5 V, 0 ukuya ku-10 V, 0 ukuya ku-20 mA, 0 ukuya ku-50 mV. | |

| Imo Yokulawula | I-PID, IVULIWE/YAYIVAMILE, iManuwali okanye ulawulo lwenkqubo yePID (Ramp/Ulawulo lokucwina). |

| Lawula iPhumo | I-Relay output: SPDT (SPST: 1/16 DIN kunye ne-1/32 DIN ubukhulu), Max. umthwalo 250 VAC, 3A umthwalo resistive. |

| Umqulutagi-pulse output: DC 14 V, Max. imveliso yangoku 40 mA. | |

| Imveliso yangoku: I-DC 4 ukuya kwi-20 mA imveliso (Umthwalo wokumelana: Max. 6000). | |

| Umgca voltage imveliso: 0 ukuba 5 V, 0 ukuba 10 V * (B Series kuphela). | |

| Bonisa Ukuchaneka | I-0 okanye i-1 idijithi ekunene kwendawo yesishumi (ikhethiwe). |

| Sampling Range | Igalelo le-Analog: 150 msec / nge-scan nganye Thermocouple okanye iPlatinum RTD: 400 cosec / scan nganye. |

| RS-485 Unxibelelwano | I-MODBUS® ASCII/RTU iprothokholi yonxibelelwano. |

| Ukunyangwa kweVibration | I-10 ukuya ku-55 Hz, i-10 m/s2 i-10 min, nganye kwi-X, Y kunye ne-Z imiyalelo. |

| Ukuxhathisa okothusayo | Max. 300 in/s2, 3 amaxesha kwi 3 axes nganye, 6 imiyalelo. |

| Ubushushu obugciniwe | 32°F ukuya ku-122°F (0°C ukuya +50°C). |

| Ubushushu boGcino | -4°F ukuya ku-150°F (-20°C ukuya +65°C). |

| Ukuphakama | 2000 m okanye ngaphantsi. |

| Ubuntu bezizalwane | 35% tp 80% (non-condensing). |

| Uhlobo lwe-Thermocouple kunye noLuhlu lobushushu | ||

| Uhlobo Loluvo Loluvo Lobushushu | Umboniso we-LED | Uluhlu lobushushu |

| Uhlobo lwe-Thermocouple TXK | -328 ~ 1472°F (-200 ~ 800°C) | |

| Uhlobo lwe-Thermocouple U | -328 ~ 932°F (-200 ~ 500°C) | |

| Uhlobo lwe-Thermocouple L | -328 ~ 1562°F (-200 ~ 850°C) | |

| Uhlobo lwe-Thermocouple B | -212 ~ 3272°F (-100 ~ 1800°C) | |

| Uhlobo lwe-Thermocouple S | -32 ~ 3092°F (0 ~ 1700°C) | |

| Uhlobo lwe-Thermocouple R | -32 ~ 3092°F (0 ~ 1700°C) | |

| Uhlobo lwe-Thermocouple N | -328 ~ 2372°F (-200 ~ 1300°C) | |

| Uhlobo lwe-Thermocouple E | -32 ~ 1112°F (0 ~ 600°C) | |

| Uhlobo lwe-Thermocouple T | -328 ~ 752°F (-200 ~ 400°C) | |

| Uhlobo lwe-Thermocouple J | -148 ~ 2192°F (-100 ~ 1200°C) | |

| Uhlobo lwe-Thermocouple K | -328 ~ 2372°F (-200 ~ 1300°C) | |

| Uhlobo lwe-RTD kunye noHlelo lobushushu | ||

| Uhlobo Loluvo Loluvo Lobushushu | Umboniso we-LED | Uluhlu lobushushu |

| I-Platinum Resistance (Pt100) | -328 ~ 1472°F (-200 ~ 800°C) | |

| I-Platinum Resistance (JPt100) | -4 ~ 752°F (-20 ~ 400°C) | |

| Umqulutage Uhlobo lwegalelo kunye noHlelo lokuNgenisa | ||

| Umqulutage Uluhlu lweNgeniso | Umboniso we-LED | Uluhlu lobushushu |

| 0 ~ 50mV Igalelo leAnalog | -999 ~ 9999 | |

| 0V ~ 10V Igalelo leAnalog | -999 ~ 9999 | |

| 0V ~ 5V Igalelo leAnalog | -999 ~ 9999 | |

| Uhlobo loNgeniso lwangoku kunye noHlelo loNgeniso | ||

| Uhlobo Longeniso lwangoku | Umboniso we-LED | Uluhlu lobushushu |

| 4 ~ 20mA Igalelo leAnalog | -999 ~ 9999 | |

| 0 ~ 20mA Igalelo leAnalog | -999 ~ 9999 | |

UKULUMKELA

![]() INGOZI

INGOZI

Ukothuka koMbane!

- Ungazichukumisi iitheminali ze-AC ngelixa umbane unikwa isilawuli ukuthintela ukothuka kombane.

- Qinisekisa ukuba amandla avaliwe ngelixa ujonga iyunithi ngaphakathi.

- Isimboli

ibonisa ukuba lo Mlawuli ukhuselwe kuyo yonke

ibonisa ukuba lo Mlawuli ukhuselwe kuyo yonke

I-DOUBLE INSUULATION okanye i-INFORCED INSULUTION (elingana neKlasi II ye-IEC 536).

![]() ISILUMKISO

ISILUMKISO

Faka isilawuli kwindawo engayi kuba phantsi kobushushu obugqithisileyo, ukothuka, okanye ukungcangcazela. Zonke iimodeli zenzelwe ukunyuswa kwiphaneli evalelweyo.

- Ngalo lonke ixesha sebenzisa iitheminali ezicetyiswayo ze-solder-less: Iitheminali zefolokhwe ezinokwahlulwa (i-M3 screw, ububanzi yi-7.0mm (6.0mm ye-32B Series), i-diameter ye-3.2mm).

Ubungakanani Screw: M3 x 6.5 (Nge 6.8 x 6.8 square washer). Ubungakanani Screw for 32B Series: M3 x 4.5 (Nge 6.0 x 6.0 iwasha square). I-orque yokuqinisa ecetyiswayo: 0.4 Nm (4kgf.cm). Ucingo olusebenzayo: Ucingo oluqinileyo / olujijekileyo lwe-2 mm2, 12AWG ukuya kwi-24AWG. Nceda uqiniseke ukuba uziqinise ngokufanelekileyo. - Musa ukuvumela uthuli okanye izinto zangaphandle ukuba ziwele ngaphakathi kwisilawuli ukunqanda ukungasebenzi kakuhle.

- Ungaze uguqule okanye uqhaqhe isilawuli.

- Musa ukuqhagamshela nantoni na kwiitheminali "Azisetyenziswanga".

- Qinisekisa ukuba zonke iingcingo ziqhagamshelwe kwi-polarity echanekileyo yeetheminali.

- Musa ukufaka kunye/okanye ukusebenzisa isilawuli kwiindawo eziphantsi: Uthuli okanye iigesi ezidliwayo kunye nolwelo, ukufuma okuphezulu kunye nemitha ephezulu yemitha, ukungcangcazela kunye nokothuka, ivolthi ephezulu.tage kunye nefrikhwensi ephezulu.

- Amandla kufuneka acime xa ufaka iingcingo kunye nokutshintsha inzwa yobushushu.

- Qinisekisa ukuba usebenzisa iingcingo zokuhlawula ezihambelana neentlobo ze-thermocouple xa ukhulisa okanye udibanisa iingcingo ze-thermocouple.

- Nceda sebenzisa iingcingo ezinoxhathiso xa usandisa okanye udibanisa iplatinam resistance sensor (RTD).

- Nceda ugcine ucingo lube mfutshane kangangoko xa ufaka i-platinam isivamvo sokuxhathisa (RTD) kwisilawuli kwaye nceda ulandele iingcingo zamandla kangangoko unakho ukusuka kwiingcingo zokulayisha ukunqanda ukuphazamiseka kunye nokwenza ingxolo.

- Esi silawuli luhlobo oluvulekileyo lweyunithi kwaye kufuneka lubekwe kwindawo ebiyelweyo kude nobushushu obuphezulu, ukufuma, amanzi athontsizayo, izinto ezidliwayo, uthuli oluphuma emoyeni kunye nokungcangcazela kombane okanye ukungcangcazela.

- Nceda uqinisekise iintambo zombane kunye nemiqondiso evela kwizixhobo zonke zifakelwe ngokufanelekileyo phambi kokunika amandla isilawuli, kungenjalo kunokuthi kwenzeke umonakalo omkhulu.

- Nceda ungasebenzisi iasidi okanye ulwelo lwealkaline ukucoca. Nceda usebenzise ilaphu elithambileyo, elomileyo ukucoca isilawuli.

- Lindela ubuncinane umzuzu omnye emva kokuba amandla enqanyuliwe ukuvumela i-capacitors ukuba ikhuphe, kwaye nceda ungachukumisi nayiphi na isiphaluka sangaphakathi ngaphakathi kweli xesha.

- Esi sixhobo asikho isitshixo sombane okanye ifyuzi. Ngoko ke, ukuba i-fuse okanye iswitshi yamandla iyadingeka, faka ukhuseleko olusondeleyo kwisixhobo. Ukalo lwefuse olucetyiswayo: Ilinganiswe voltage 250 V, Ilinganiswe ngoku 1 A. Uhlobo lwe-Fuse: I-fuse ye-Time-lag.

- Phawula: Lo mlawuli akaboneleli ngokhuseleko oludlulayo. Ukusetyenziswa kwemveliso kufuna ukuba isixhobo esifanelekileyo sokukhusela i-overcurrent kufuneka songezwe ukuqinisekisa ukuthotyelwa kwayo yonke imigangatho yombane efanelekileyo kunye neekhowudi. (Ilinganiswe kwi-250 V, i-15 Amps ubuninzi). Isixhobo esifanelekileyo sokuqhawula kufuneka sinikezelwe kufutshane nesilawuli kufakelo lokusetyenziswa kokuphela.

Imilinganiselo yangaphandle

Imilinganiselo ikwimilimitha (intshi)

1.888.610.7664

![]() www.calcert.com

www.calcert.com

sales@calcert.com

Amaxwebhu / Izibonelelo

|

I-Dwyer 4B Series 8B DIN Temperature Process Loop Controller [pdf] Incwadi Yomyalelo I-4B Series ye-8B ye-DIN ye-Temperature ye-Loop Controller, i-4B Series, i-8B ye-DIN ye-Temperature ye-Loop Controller, i-Process Loop Controller, i-Loop Controller |